Evaporation Residue Testing chain store|100 degree evaporation residue : convenience store 13.0 MICROBIAL LIMIT TEST TOTAL AEROBIC BACTERIAL COUNT: Media preparation-Take 40 gm of Soybean Casein Digest Agar medium in 1000 ml volumetric flask and dissolve by gentle heating and make the volume 1000 ml then sterilized for 15 min at 121°C and 15 lbs. pressure.Procedure-Take six plate and take 0.1 ml in three plats and 1.0 ml for other . Derpixon ️ publicou um status no Twitter com uma imagem de um personagem de anime. Veja o que ele disse e confira a sua arte incrível.

{plog:ftitle_list}

web22 de out. de 2021 · Como Evitar Códigos de Erro Win32. É possível que existam milhares de códigos de erro Win32, e alguns deles são inevitáveis. As razões específicas dos códigos de erro do Win32 são difíceis de descobrir, mas você pode tentar as seguintes maneiras para evitar que eles ocorram e proteger seu computador de eventuais perdas de dados .

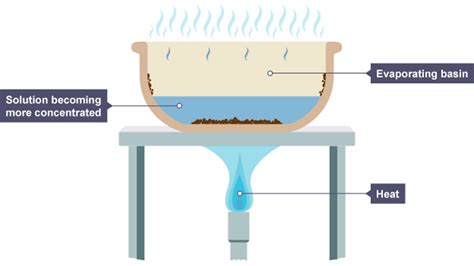

residue on evaporation method

Summary of method. 2.1 A volume of filtered sample that will yield less than 200 mg residue is evaporated just to dryness on a steam bath. The residue is dried at 105°C for 2.0 h, cooled in a desiccator, and immediately weighed.This analysis determines the mass of the residue left behind when the water in the sample is evaporated at different temperatures.

100 degree evaporation residue

1. Application. 1.1 This method may be used to determine the total-solids concentration of any natural or treated water or industrial waste. 1.2 Total residue represents the sum of both .

3.2 This test method for residue by evaporation tends to give an asphaltic residue lower in penetration and ductility than the distillation test method (D6997). Material may be accepted but shall not be rejected as failing to meet specifications containing requirements for determination of residue by distillation, on data obtained by evaporation.

13.0 MICROBIAL LIMIT TEST TOTAL AEROBIC BACTERIAL COUNT: Media preparation-Take 40 gm of Soybean Casein Digest Agar medium in 1000 ml volumetric flask and dissolve by gentle heating and make the volume 1000 ml then sterilized for 15 min at 121°C and 15 lbs. pressure.Procedure-Take six plate and take 0.1 ml in three plats and 1.0 ml for other .

1.1 This test method covers the determination of dissolved organic and inorganic matter and colloidal material found in high-purity water used in the semiconductor, and related industries. This material is referred to as residue after evaporation (RAE). The range of the test method is from 0.001 μg/L (ppb) to 60 μg/L (ppb).

3.1.1 carbon residue, n—the residue formed by evaporation and thermal degradation of a carbon containing material. 3.1.1.1 Discussion—The residue is not composed entirely of carbon but is a coke that can be further changed by carbon pyrolysis. The term carbon residue is retained in deference to its wide common usage. D4175 4. Summary of .The bottom line? While our eyes see nothing wrong, the concealed reality of particulate contamination poses grave unseen risks to downstream production and product functionality. Only advanced testing delivers the truth about the cleanliness of precision components after intricate cleaning preparation. Going Deeper - Nonvolatile Residue - NVR .

The NaOH they add to it is to prolong shelf life. And the reaction by which sodium hypochlorite is reduced to sodium chloride consumes protons, producing even more hydroxide, so it's indeed possible that residual alkali is causing the irritation the OP is describing.

As the residue left by the distilled alcohol seems to be "highly non volatile" rather than acting on the distillation, a long column should prevent escape of aerosol. A 20 cm vigreaux is certainly short, especially if nested on flask of the liter scale! $\endgroup$ 3.2 This test method for residue by evaporation tends to give an asphaltic residue lower in penetration and ductility than the distillation test method (D6997). Material may be accepted but shall not be rejected as failing to meet specifications containing requirements for determination of residue by distillation, on data obtained by evaporation.I SO 5277, Aromatic hydrocarbons - Determination of residue on evaporation. 1) I SO 5789, Fluorinated hydrocarbons for industrial use - Deter- mina tion of non-vola Me residue. 3 Principle Evaporation of a test portion on a water bath, and drying of the residue, if any, in an oven at 110 + 2 OC to constant mass. This test method covers the determination of non-volatile matter, that is, residue on evaporation, in solvent extract from aerospace components, using a rotary flash evaporator. The summary of the test method, the apparatus for testing, reagents and materials for testing, and procedure for testing are all presented in details.

Gum Test Apparatus measures evaporation residue in aviation fuels, motor gasoline, and other volatile distillates as per standard test procedures. The HGT 915 uses air evaporation, while the HGT 917 offers the versatility of either air or steam evaporation. Both are capable of testing three 100ml samples simultaneously.The Japanese Food Sanitation Act designates the evaporation residue test as a specification for plastics that intended to contact with foods. The test conditions and migration limits for oils and fatty foods were considered on the basis of the results obtained from the evaporation residue test according to the Japanese Act and the overall migration test into olive oil according to .3.1.1 carbon residue, n—the residue formed by evaporation and thermal degradation of a carbon containing material. 3.1.1.1 Discussion—The residue is not composed entirely of carbon but is a coke that can be further changed by carbon pyrolysis. 4. Summary of Test Method 4.1 A weighed quantity of sample is placed in a glass vial

1.1 This test method covers the determination of the amount of carbon residue (Note 1) left after evaporation and pyrolysis of an oil, and is intended to provide some indication of relative coke-forming propensities.This test method is generally applicable to relatively nonvolatile petroleum products which partially decompose on distillation at atmospheric pressure.

1. Calculate the percentage of residue for each sample, as follows: Residue, % = 4 × (M a -M b) where: M a = Weight of the container and asphalt emulsion residue in grams, and M b = Tare weight of the container in grams. F. REPORTING OF RESULTS Report the percentage of residue by evaporation as the average of the three results. G. PRECAUTIONS

The term “SAP” in the context of acetic acid glacial testing likely refers to the “Saponification Value” or “Saponification Acid Value.” The Acetic Acid Glacial Testing Procedure (SAP) saponification value is a measure of .astmd693422-Standard Test Method for Residue by Evaporation of Emulsified Asphalt- 1.1This test method covers the quantitative determination of residue in emul . HOME; PRODUCTS. . Documents sold on the ANSI Standards Store .Solids, residue on evaporation at 105°C, total, gravimetric Parameter and Code: Solids, residue on evaporation at 105°C, total, I-3750-85 (mg/L): 00500 1. Application 1.1 This method may be used to determine the total-solids concentration of any natural or treated water or industrial waste. 1.2 Total residue represents the sum of both Then, the residue was stirred continuously at 155 °C until the residue surface was smooth and flat without bubbles, the temperature was increased and kept at 160 °C for 1 min. The appearances of base asphalt, SBS modified asphalt, SBS modified emulsified asphalt and evaporation residue were shown in Fig. 3.

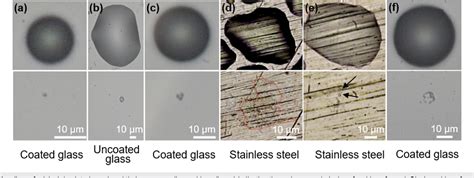

For example, evaporation of liquid into air is strongly affected by the insulating properties of the air itself, so for these experiments the process was observed in a chamber with only the liquid and vapor present, isolated from the surrounding air. . Director of the MIT Humanitarian Supply Chain Lab, within the Center for Transportation and . We found that during evaporation, droplets on the tested surfaces first shrink in height (constant contact radius mode) and then in diameter (constant contact angle mode) to form a thin liquid film, leaving behind residues of different types on the order of micrometers, as illustrated in Fig. 1.We either obtain a single residue, most likely a thin film or droplet, or .

3.1 The test may be used to indicate compositional charac-teristics of emulsified asphalt. Evaporation residue may also be subjected to other characterization tests. 3.2 This test method for residue by evaporation tends to give an asphaltic residue lower in penetration and ductility than the distillation test method (D6997). Material may be .Simple single-use design: basic assembly required testing takes 30 seconds, with easy single-motion collection, and results are available in just 3 minutes; US and eu patent-pending: the world's inaugural rapid at-home cigarette smoke residue test kit, boasting ultra-sensitivity for unparalleled accuracy; Return PolicyThis test method describes the procedure to determine the percentage of asphalt and latex (combined) in an asphaltic emulsion. The residue from this test may then be used for additional testing. This test is a modification to Section 7 of AASHTO T 59-15. B. REFERENCES AASHTO T 59 -15 – Standard Test Method for Emulsified AsphaltsCO2 transmission rate test by weighing method: Water vapor transmission rate test by inverted cup method: Non-destructive test for packaging seal performance: Multi-station packaging pressure test: Tensile test of packaging materials with ultra-long elongation: Heat-seal strength test for cap films of medical bottles, yogurt cups and jelly cups

water vapor permeability test procedure supplier

Measure evaporation residue in aviation fuels, motor gasolines, and other volatile distillates in accordance with ASTM D 381, ISO 6246, EN 5 and IP 131 test methods. The HGT 915 uses air evaporation, while the HGT 917 offers the versatility of either air or steam evaporation.

transfer, and the formation of cold residue nuclide by evaporating γ-rays, neutrons, light charged particles and binary fission. The production cross section of the su-perheavy residue is estimated by the sum of partial wave with the angular momentum J at incident center of mass energy Ec.m. as, σER(Ec.m.) = π¯h2 2µEc.m. JX max J=0

Photos TAÇA BAND VALE 2023 - 3 RODADA - COMPLEXO: CAMPO E. C. VILA GARCIA (JACAREÍ) sunday - 11.12.23 - E. C. VILA GARCIA: RUA PAULO IAZZETI, Nº 31, VILA .

Evaporation Residue Testing chain store|100 degree evaporation residue